In recent years, the world of robotics has seen a significant evolution with the advent of collaborative robots, or "cobots." These innovative machines are transforming industries by working alongside humans, rather than replacing them. In this article, we will delve into what cobots are, their unique characteristics, and the various roles they play in today's workplaces.

Defining Cobots:

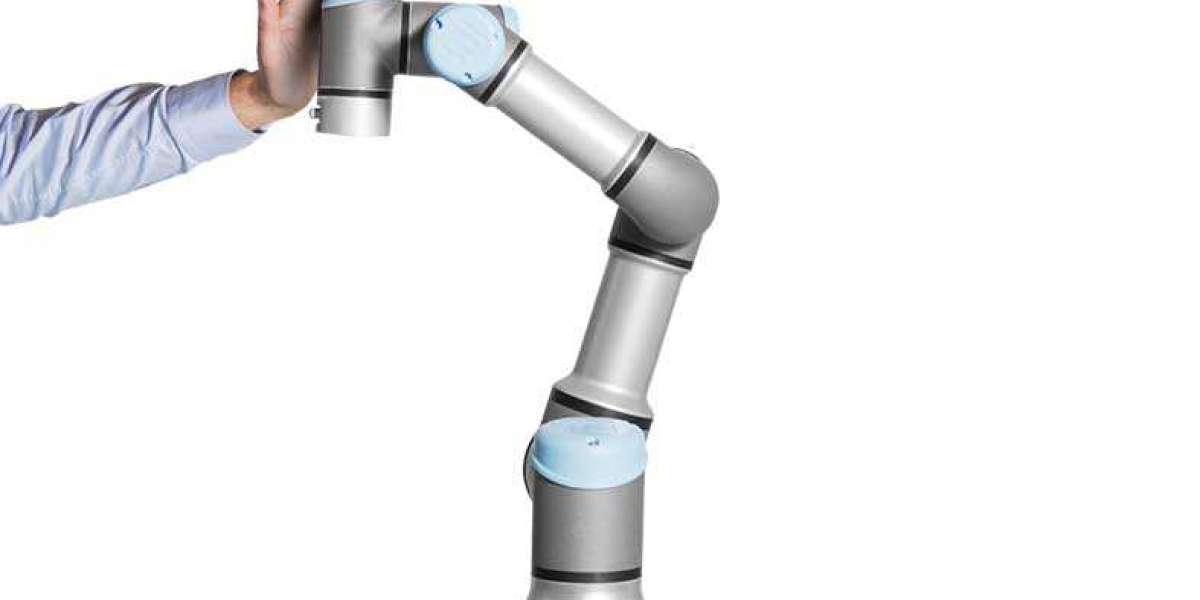

Collaborative robots, or cobots for short, are a specialized category of robots designed to collaborate and interact safely with humans in a shared workspace. Unlike traditional industrial robots, which typically work in isolation behind safety barriers, cobots are intended to work in close proximity to humans without posing a danger.

Key Characteristics of Cobots:

1. Safety Features: The primary characteristic that sets cobots apart is their enhanced safety features. They are equipped with sensors and advanced control systems that allow them to detect and respond to human presence. If a human gets too close, cobots can slow down or stop their movements, minimizing the risk of accidents.

2. Ease of Programming: Cobots are designed to be user-friendly, with intuitive programming interfaces that don't require extensive technical expertise. This allows non-engineers to teach cobots tasks easily, making them accessible to a broader range of industries.

3. Flexibility: Cobots are highly adaptable and can be quickly reprogrammed for different tasks. Their flexibility makes them suitable for small-batch production, where frequent changes in tasks are common.

4. Size and Portability: Cobots are often compact and lightweight, making them easy to deploy in various settings. Their portability allows them to move from one workstation to another, increasing their versatility.

Applications of Cobots:

Cobots have found applications across various industries, including manufacturing, healthcare, logistics, and more. Here are some roles they play:

1. Manufacturing: Cobots are used for tasks such as pick-and-place, assembly, and quality control in manufacturing plants. They can work alongside human operators, increasing production efficiency and product consistency.

2. Healthcare: In healthcare settings, cobots can assist with tasks like medication dispensing, patient lifting, and even surgical procedures, reducing the physical strain on healthcare professionals.

3. Logistics and Warehousing: Cobots are employed in warehouses for tasks like order picking, packing, and inventory management. They help streamline operations and improve order accuracy.

4. Agriculture: Cobots are used in precision agriculture for tasks like planting, weeding, and harvesting crops. They can work in challenging outdoor environments while reducing the need for manual labor.

5. Education and Research: Cobots are also used in educational institutions and research facilities to teach robotics concepts and conduct experiments safely.

The Future of Cobots:

As technology continues to advance, the capabilities of cobots will only grow. Future developments may include improved sensory perception, enhanced AI and machine learning capabilities, and increased integration with other technologies like 5G and the Internet of Things (IoT).

In conclusion, collaborative robots, or cobots, represent a significant advancement in robotics technology. Their ability to work safely alongside humans and their versatility make them valuable assets in a wide range of industries. As cobot technology continues to evolve, we can expect even more exciting applications and innovations in the years to come, further reshaping the way we work and live.