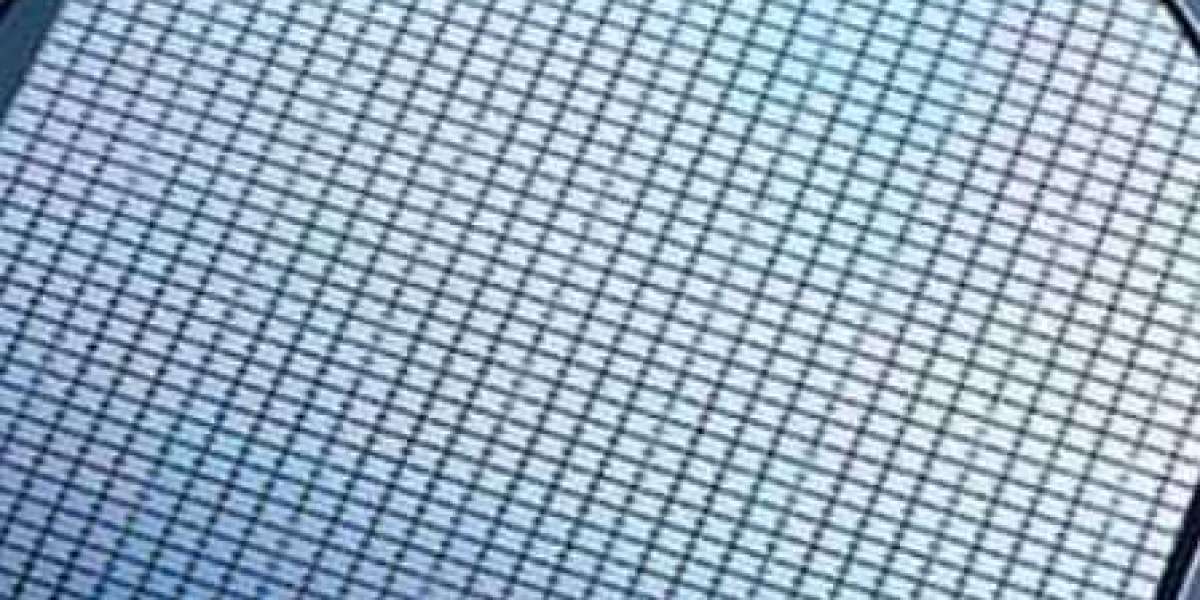

In the realm of semiconductor manufacturing and electronics assembly, the process of die attach plays a crucial role in ensuring the reliability and performance of microelectronic devices. Die attach involves bonding semiconductor chips or dies to their respective substrates or packages, forming a secure and electrically conductive connection. At the heart of this process lie die attach materials – specialized adhesives or solders designed to meet the unique requirements of various industries. In this blog, we'll delve into the world of die attach materials, exploring their versatility and applications across different sectors.

Semiconductor Industry:

Epoxy Resins:

Epoxy resins are widely used as die attach materials in the semiconductor industry due to their excellent adhesion properties, thermal stability, and electrical insulation characteristics.

These materials provide strong mechanical bonding between the semiconductor die and its substrate, ensuring reliable performance under harsh operating conditions.

Epoxy-based die attach materials are suitable for a wide range of semiconductor devices, including integrated circuits (ICs), power modules, and light-emitting diodes (LEDs).

Silver Sintering Pastes:

Silver sintering pastes offer an alternative to traditional solder-based die attach materials, particularly for high-temperature applications.

By sintering silver particles under pressure and elevated temperatures, these pastes form robust and thermally conductive bonds between the die and substrate.

Silver sintering technology is gaining traction in power electronics and automotive applications, where reliability, thermal management, and longevity are paramount.

Automotive Industry:

Silver Epoxy Adhesives:

In automotive electronics, where reliability and thermal performance are critical, silver epoxy adhesives find widespread use as die attach materials.

These adhesives offer high thermal conductivity, ensuring efficient heat dissipation from power semiconductor devices such as insulated gate bipolar transistors (IGBTs) and diodes.

Silver epoxy die attaches provide strong mechanical bonding and can withstand the temperature fluctuations and vibrations encountered in automotive environments.

Lead-Free Solder Pastes:

With increasing regulatory pressure to eliminate lead-based materials, lead-free solder pastes have become the preferred choice for die attach in automotive electronics.

These pastes typically consist of tin, silver, and copper alloys, offering excellent solderability, thermal conductivity, and mechanical strength.

Lead-free solder pastes comply with environmental regulations while maintaining the reliability and performance required for automotive applications.

Consumer Electronics:

Electrically Conductive Adhesives (ECAs):

In the consumer electronics sector, ECAs serve as versatile die attach materials for bonding semiconductor chips in devices such as smartphones, tablets, and wearables.

ECAs provide both electrical conductivity and adhesive properties, allowing for efficient signal transmission and secure attachment of components.

These materials offer flexibility in design and manufacturing processes, enabling miniaturization and improved reliability in compact electronic devices.

Anisotropic Conductive Films (ACFs):

ACFs are commonly used in the assembly of flat panel displays, touchscreens, and flexible electronics, where fine-pitch interconnections are required.

These films contain conductive particles dispersed in a non-conductive adhesive matrix, allowing for selective electrical conduction in specific directions.

ACFs facilitate the precise bonding of semiconductor dies to flexible substrates, enabling the production of high-resolution displays and next-generation electronic devices.

Aerospace and Defense:

Eutectic Die Attach Alloys:

Aerospace and defense applications demand die attach materials capable of withstanding extreme temperatures, mechanical stresses, and harsh environmental conditions.

Eutectic die attach alloys, such as gold-tin (AuSn) and gold-germanium (AuGe), offer superior thermal stability, hermetic sealing, and long-term reliability.

These alloys are commonly used in the assembly of space-grade electronic components, missile guidance systems, and avionics equipment, where failure is not an option.

Conductive Adhesive Films:

For lightweight and miniaturized electronic systems deployed in aerospace and defense applications, conductive adhesive films provide a viable solution for die attachment.

These films offer low outgassing properties, high thermal conductivity, and excellent adhesion to a variety of substrates, including ceramics and metal alloys.

Conductive adhesive films enable the integration of semiconductor devices into ruggedized enclosures, ensuring optimal performance in harsh operating environments.

In conclusion, die attach materials play a pivotal role in the manufacturing and assembly of microelectronic devices across a diverse range of industries. From semiconductor chips to automotive electronics, consumer gadgets to aerospace systems, the choice of die attach material directly impacts the reliability, performance, and longevity of electronic products. By understanding the unique requirements of each industry and selecting the appropriate die attach materials, manufacturers can ensure the seamless integration of semiconductor dies into their end products, thereby enhancing functionality, durability, and customer satisfaction.

Top of Form